Geissberger Farmhouse Cider, situated on Langmaid Road in Clarington, Ont., is a family-run cider press business managed by brothers Gordon and Garry Geissberger, alongside their families.

The family has tended the farm for three generations since their grandparents, Hans and Emma Geissberger, immigrated from Switzerland in 1925.

The Geissbergers’ pressed ciders are made from a mix of apples from their own farm as well as those locally sourced. They source the apples from the Durham Region farms: Maple Grove Orchards, Pingles Farm, Nature’s Bounty and Stroud Farms.

The business offers cider milling services to other local farmers aiming to create their own brand of ciders.

In addition, they offer the only mobile apple pressing service in Ontario to farmers located outside Durham Region. While this was a unique offering in the province, in the last year they’ve chosen to slow the mobile service down to focus on responsibilities at home.

Garry reflected on the origins of their apple pressing venture. Garry said the apple pressing started as a hobby for his grandfather.

“Our grandfather, who came from Switzerland, liked apple cider, and on the dairy farm that he had, there was an apple orchard,” he said. “He always sent the apples away to get pressed and brought the cider home.”

This tradition evolved in 1970 when their grandfather’s nephew, Max, visited from Switzerland and constructed their first apple cider press, used until 2012.

In 2012, the Geissberger brothers bought a new mobile apple presser, a pioneering technology in Ontario. It was basically a mobile apple cider mill on wheels.

Gordon said for the past ten years, this mobile cider mill enabled them to serve customers within a three-and-a-half-hour radius of the farm. “We had customers in Kingston, Milford area, Port Elgin, up by Owen Sound, and Niagara-on-the-Lake,” he said.

Though they’ve been “slowing down” their mobile pressing business, they still continue to serve distant farms.

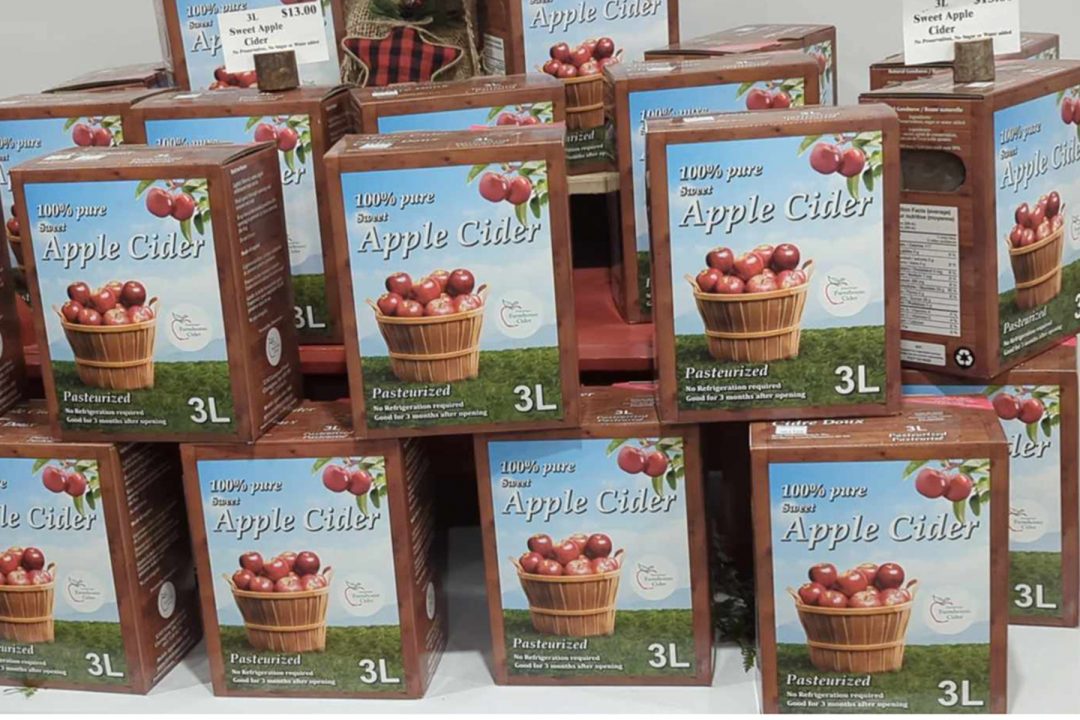

Everything is sourced locally down to the bags and boxes they package their ciders in. The boxes are made in Scarborough, and the bags are from Mississauga.

“One nice thing about our bag and box packaging is that there’s no refrigeration required, and refrigeration is a big greenhouse gas emitter,” Gordon said.

Gordon said he and his brother are proud that they keep their carbon footprint very small when making apple cider. “even [the] boxes for our bag-and-box packaging are Forest Sustainable Certified (FSC),” he said.

Garry said if the machine works as intended, they can churn out about 400 litres of apple cider in an hour. “Which would be about two of those big 20-bushel apple bins an hour,” he said.

“If you were to follow one apple through [the process], it might be 20 minutes from the time it entered the shoot till it came out in the cider,” Garry said.

The apples are shovelled in a chute, where they are inspected. Anything that shouldn’t be there, like excess twigs, are pulled out.

The apples are washed as they go up an elevator, dropped into a chopper, mashed into a pulp, and poured onto a press.

The apple mash is placed in layers, pressed, and put into a stainless steel tank.

“We added on a dairy filter, which is a very fine filter to take out any small particles we may not want in there,” Garry said.

After being pasteurized, the hot apple cider goes into the filler machine and is put into bags. “When it cools, it vacuum seals itself in the bag,” He said.

This process ensures no air in the bag could start any fermentation of their product. Garry said this is why they don’t need any preservatives.

Their cider has a one-year shelf life and lasts up to three months once opened.

“Like I say,” Garry said, “no preservatives, no sugar added, no water added, no refrigeration required. It’s a pure product.”